P3

What is Industry 4.0?

Industry 4.0 (also known as the 4th Industrial Revolution), is the trend towards automation and data exchange in manufacturing technologies and processes which include cyber-physical systems (CPS), the internet of things (IoT), industrial internet of things (IIOT), cloud computing, cognitive computing and artificial intelligence.

The characteristics given for the Industry 4.0 strategy is the customization of products under the conditions of highly flexible mass – production.

https://www.forbes.com/sites/bernardmarr/2016/04/05/why-everyone-must-get-ready-for-4th-industrial-revolution/#44ebfa1b3f90

What does the concept include?

The concept includes:

- Smart manufacturing

- Smart factory

- Lights out (manufacturing) also known as dark factories

- Industrial internet of things also called internet of things for manufacturing

Principles in Industry 4.0

There are four design principles in Industry 4.0:

Interconnection: The ability of machines, devices, sensors, and people to connect and communicate with each other via the Internet of Things (IoT) or the Internet of People (IoP)

Information transparency: The transparency afforded by Industry 4.0 technology provides operators with immense amounts of useful information needed to make appropriate decisions.

Technical assistance: Firstly, the ability of assistance systems to support humans by visualizing information comprehensively for making informed decisions and solving urgent problems on short notice. And Secondly, the ability of cyber physical systems to physically support humans by conducting a number of tasks that are too exhausting, or unsafe.

Decentralised decisions: The ability of cyber physical systems to make decisions on their own and to perform their tasks as autonomously as possible.

https://ieeexplore.ieee.org/document/7427673?arnumber=7427673&newsearch=true&queryText=industrie%204.0%20design%20principles

https://en.wikipedia.org/wiki/Industry_4.0

Tasks:

H5P: https://h5p.org/node/705021

History of Industry 4.0

The History of Industry 4.0

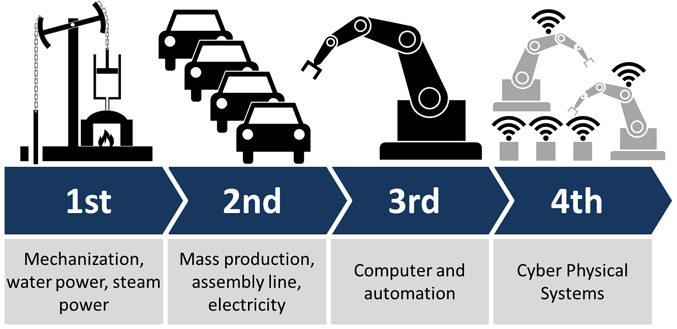

The following image shows the stages in which the development of the industrial manufacturing systems has developed from manual labour towards Industry 4.0. The has been described as the path through the four industrial revolutions.

Image from www.wikipedia.com

The first industrial revolution began with the mechanization and mechanical power generation in 1800s. It brought the transition from manual work to the first manufacturing processes; mostly in the textile industry.

The second industrial revolution was triggered by electrification that enabled industrialization and mass production.

The third industrial revolution is characterized by the digitalization with introduction of microelectronics and automation. In manufacturing this facilitates flexible production, where a variety of products is manufactured on flexible production lines with programmable machines. Such production systems however still do not have flexibility concerning production quantity.

Today we are witnessing the fourth industrial revolution that was triggered by the development of Information and Communications Technologies (ICT). Its technological basis is smart automation of cyber-physical systems. The consequence of this new technology for industrial production systems is the reorganization of automation systems to self-organising cyber physical production systems that allows flexible mass custom production and flexibility in production quantity.

https://online-journals.org/index.php/i-jim/article/viewFile/7072/4532

Tasks:

H5P: https://h5p.org/node/705116

When did Industry 4.0 begin?

Introducing Industry 4.0 to the public

The term Industry 4.0 was first publicly introduced in 2011 as “Industry 4.0” by a group of representatives from different fields (such as business, politics, and academia) under an initiative to enhance the German competitiveness in the manufacturing industry. The German federal government adopted the idea in its High-Tech Strategy for 2020. Subsequently, a Working Group was formed to further advise on the implementation of Industry 4.0.

https://www.cleverism.com/industry-4-0/

Following that, a German government memo was released in 2013 and was one of the first times that ‘Industry 4.0’ was formally introduced. The high-tech strategy document outlined a plan to almost entirely computerize the manufacturing industry without the need for human involvement.

Angela Merkel, the German chancellor, spoke of the concept in January 2015 at the World Economic Forum in Davos, calling ‘Industry 4.0’ the way that we “deal quickly with the fusion of the online world and the world of industrial production.” The German government started with investing 200 million euros to encourage research across academia, business, and government. Parallel to that, big German corporates and SMEs are investing some 650 million euros to speed up the development of ICT & “Industry 4.0” related technologies. The German Companies plan to invest around 10.9 billion euros in the evolution of “Industry 4.0” in the upcoming ten years.

Since the German announcement back in 2011, many other countries immediately realized the value of “Industry 4.0” concept and technologies and embarked efforts to develop it and participate in shaping it. Following to German government initiative, and in 2012, the US started the Smart Manufacturing Leadership Coalition (SMLC). SMLC is NGO combining manufacturers, suppliers, technology firms, government agencies, universities, and laboratories that all have the common goal of advancing the way of thinking behind “Industry 4.0”.

https://www.linkedin.com/pulse/industry-40-fourth-industrial-revolution-hatem-azzam/

Tasks:

H5P: https://h5p.org/node/705132

World of Work

Industry 4.0 and The New World of Work

The operational transformation will require technology to support new ways of thinking about jobs, the way people who do them, and the information they need to do it.

The digitisation of processes and systems is enabling the better collection and analysis of data, and potentially companies will be able to make better decisions faster. But more companies are beginning to realize that the speed at which business and technology change is not just new ways of thinking about technology, but about the change of the nature of the work itself.

https://www.automationworld.com/products/control/news/13316129/industry-40-and-the-new-world-of-work

Adopting Industry 4.0

Companies will face huge challenges in the adoption of these new technologies. To build and sustain these new technologies to full implementation, they will need to broaden and deepen their knowledge on digital technologies and the related fields —and then develop and implement tailored digital manufacturing strategies.

https://www.bcg.com/capabilities/operations/embracing-industry-4.0-rediscovering-growth.aspx

What does Industry 4.0 mean for the work force?

As mentioned in previous chapters, Industry 4.0 will have a massive impact on the economy and by consequence to the labour market. According to Dirk Hahn (CEO and Strategic Director of Hays in Germany) “it is estimated that as machines increasingly run themselves, we will inevitably see middle-skilled roles disappearing”. He also continues by saying “improvements in technology will likely lead to a ‘hollowing out’ of jobs distribution, whereby some middle-skilled jobs will disappear.” On the other hand, he explains later on, how more jobs will be created in both lower and higher-skilled occupations, ultimately meaning that automation will generate more jobs than it will destroy.

https://social.hays.com/2018/11/12/industry-4-0-job/

Here you can find an interesting article from the Guardian, by Richard Partington explaining how “Robots in workplace ‘could create double the jobs they destroy”.

https://www.theguardian.com/business/2018/sep/17/robots-in-workplace-could-create-double-the-jobs-they-destroy

Tasks:

H5P: https://h5p.org/node/705352

Industry 4.0 Challenges

The challenges in implementing Industry 4.0 are Economic, Social, Political and Organisational/Internal.

Economic

- High economic costs

- Business model adaptation

- Unclear economic benefits/excessive investment

Social:

- Privacy concerns

- Surveillance and distrust

- General reluctance to change by stakeholders

- Threat of redundancy of the corporate IT department

- Loss of many jobs to automatic processes and IT-controlled processes, especially for blue collar workers

Political

- Lack of regulation, standards and forms of certifications

- Unclear legal issues and data security

Organisational/ Internal

- IT security issues, which are greatly aggravated by the inherent need to open up those previously closed production shops

- Reliability and stability needed for critical machine-to-machine communication (M2M), including very short and stable latency times

- Need to maintain the integrity of production processes

- Need to avoid any IT snags, as those would cause expensive production outages

- Need to protect industrial know-how (contained also in the control files for the industrial automation gear)

- Lack of adequate skill-sets to expedite the transition towards the fourth industrial revolution

- Low top management commitment

- Insufficient qualification of employees

Here you can see an Interview by UATV English (Date: 5th of October 2017) – Challenges of the Fourth Industrial Revolution.

A brief explanation on how the Fourth Industrial Revolution is expected to be a huge challenge for educational institutions. How can they prepare students with the skills they need to be competitive in the global labour market in years to come?

https://www.youtube.com/watch?v=mFJ91lwFUVs

Tasks:

H5P: https://h5p.org/node/713071

Benefits of Industry 4.0 in the World of Work

Industry 4.0 technologies could potentially transform the manufacturing chain completely. The benefits of digitization are significant from the efficiency of production, to the deployment of innovative products and services.

Revenue gains

According to a report by PwC (https://i4-0-self-assessment.pwc.nl/i40/study.pdf) digitalised services and products create €110 billion additional profit per year in Europe. Revolutionary companies with digitalised services and products have noticed a significant growth in the last few years. Almost 50% of businesses who are converting to Industry 4.0 are expected to double their revenue in the next 5 years of implementation. Also, one in five businesses expect a 20% sales rise.

With the help of big data analytics, companies can also gain a deeper understanding of customer needs. The new information provided, can be applied to product development and used to build up customer interactions.

Increased efficiency and productivity

An article published in OECD.org by McKinsey & Company (http://www.oecd.org/dev/Digital-in-industry-From-buzzword-to-value-creation.pdf) estimate that converting to automation and digitalisation can boost productivity in technical professions by 45% – 55%. IoT (Internet of Things) has already been applied in large companies such as Siemens, Airbus, Cisco and many other companies in the Industry, which can now create more advanced IoT ecosystems of devices developed by sellers. The initial products enable seamless, fast and secure cross-platform connectivity and data exchanges between different IioT (Industrial Internet of Things) systems.

Human-robot teams are appearing in the factories now. The new generation robots are able to help manufacturers automate parts of the production process in order to get the products to the market faster. The MIT technology review (https://www.technologyreview.com/s/530696/how-human-robot-teamwork-will-upend-manufacturing/) estimates that the collaboration with the robot teams will reduce the workers time by 85%.

Improved supply/demand matching

Cloud-based inventory management solutions enable better interactions with suppliers. Instead of operating in “individual silo”, you can create seamless exchanges and ensure that companies that have applied Industry 4.0 technologies to their system have:

- High service-parts fill rates;

- High levels of product uptime with minimal risk;

- Higher customer service levels.

By pairing their inventory management system with a big data analytics solution, they will improve their demand by at least 85%. They can also perform real-time supply chain optimization and gain more visibility into the possible tailbacks, and expanding their growth.

Tasks:

H5P: https://h5p.org/node/725505

Industry 4.0 Drivers

According to a publication by Nordia (https://www.reliableplant.com/Read/30933/factors-driving-industry) the 3 main drivers of Industry 4.0 are Data, Connectivity and the Customer.

Data:

An introduction in the use and consecutive data can be attributed to the advancement of Industry 4.0 and has “forced” businesses in a way to review their systems. The rise in data volumes has led to the term “big data.” This has caused a greater need than ever for companies to store and gather information and make better use of it. Organizations are now making use of historic data with advanced analytics, by enabling cognitive machines to self-diagnose and configure.

Connectivity:

Global supply chains are becoming increasingly common but are accompanied by efficiency issues due to distance and time zones. The Industry 4.0 solution for this is to create a virtual global factory, which means creating a network of businesses from various regions that can resolve issues of connectivity between companies and also improve the relationship between the customer and supplier.

Customer

Customer’s needs have also empowered Industry 4.0. Innovative technology, such as 3-D printing, enables the conversion of a digital design into a physical product. This means that all products are materialising at a faster pace at an industrial level. By consequence, products can become more customised to the individuals, although they are made at a mass production level.

Using a digital system to design and create products creates great flexibility for both B2B transactions and to the customer (the end user). By combining the customer’s input, the data analysis and response may mean that in the future a digital ecosystem will be created whereby human decision is augmented through algorithms.

Tasks:

H5P: https://h5p.org/node/726055

Agriculture and Industry 4.0

Digitalisation of agriculture

Industry 4.0 is transforming the production capabilities of all industries, including the agricultural sector. Connectivity is a vital element of this transformation and IoT a key enabling this technology that is increasingly taking part of the agricultural equipment.

The digitalisation of agriculture is based on the development and introduction of new tools and machines in production.

Transformation of the production methods and tools

Connected Tractors

The implementation of Industry 4.0 to tractors are key factors of the development of the agricultural industry. Connectivity and localisation technologies (GPS) are optimizing the usage of these agricultural tools. This includes driver’s assistance to enhance routes and decrease harvesting and crop treatment, while reducing fuel use. But it also relies on the deployment of sensors to enable precision agriculture (PA). The sensors can better monitor and control crop treatments, enabling important gains in efficiency and productivity. In addition, connectivity is also enabling models developed by businesses to be more precise in terms of tracking by using better equipment which contributed to more precise billing of equipment use by contractors.

Automation

Another important transformation in the agricultural production process is automation. Automation will increase productivity by reducing the need for human workforce. This can take several forms, for example the automation of vehicles, the development of task specific robots that can automatically manufacture parts in the production line.

New Measurement Tools

The ability to collect more data and measurement about the production such as the quality of the soil, irrigation levels, weather conditions, presence of insects and pests. This ability also takes several forms such as sensors deployed on tractors and implements to direct deployment of sensors in the field and soil or in drones or satellite imagery to collect measurements from above.

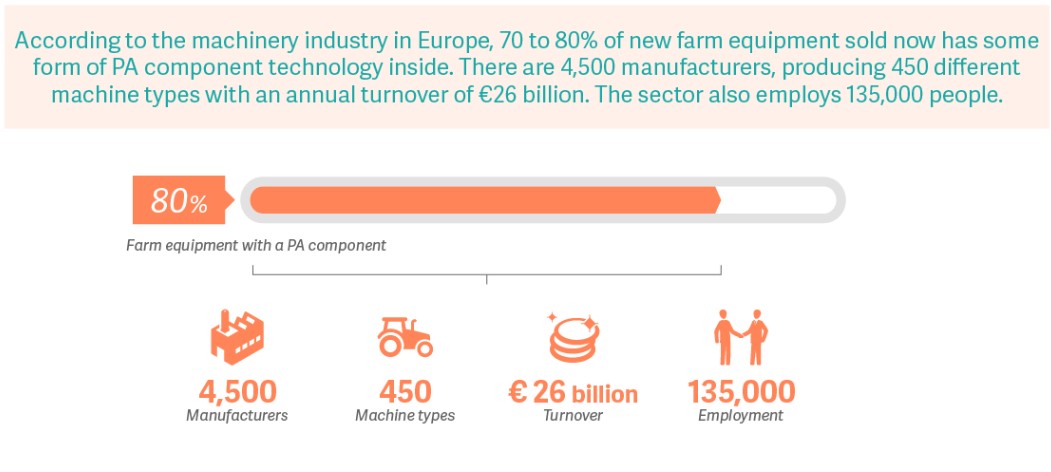

An interesting statistic provided by Euractiv:

Source: https://www.euractiv.com/section/agriculture-food/infographic/farming-4-0-the-future-of-agriculture/

Source: https://www.euractiv.com/section/agriculture-food/infographic/farming-4-0-the-future-of-agriculture/

Task:

H5P: https://h5p.org/node/726119

8.1 The need of Industry 4.0 in the Agriculture sector

Digitalisation of agriculture

Regular machines (such as tractors) in agriculture are being converted to Industry 4.0 machines, meaning that they will become self-aware and self-learning, so as to enhance the overall performance and maintenance management of agriculture.

The main needs of Industry 4.0 in agriculture sectors aim to construct an open, smart manufacturing platform for real time data monitoring, by tracking the status and positions of a product as well as to consist of the instructions to supervise farming processes.

Automation

As mentioned previously automation is an important factor and a necessity for the transformation of agriculture. It will increase productivity by reducing the need for human workforce. By reducing the workforce on the line, the workforce will have to be trained to maintain and work on the machines thus reducing costs and increase profits.

Industry 4.0 allows companies to combine productivity and speed to respond to the market faster by making their systems more productive and competitive. However, companies who choose not to follow this emerging trend, risk being excluded from a worldwide competition. Agriculture 4.0 will make it possible to accomplish smart farms through new technologies. Nevertheless, the acceptance of these technologies by individual farmers depends on other additional factors, such as usability and the identification of best practices.

Both agricultural and farmer-centred approaches are needed for this. This way, the concept of smart farming will be made sustainable for the future. In the mindset of farmers, the importance of change and development is vital to stimulate an effective and sustainable production system that will last in the future. Instead, these ideas are the basis of a competitive industry.

Task:

H5P: https://h5p.org/node/726250

8.2 Connecting Machines and Farms

Agriculture 4.0 is about connectivity

By default, the introduction of new tools and practises are needed to be incorporated in businesses in order to incorporate Agriculture 4.0 to increase productivity. To achieve that, the capability to remotely collect, use, and exchange data is necessary.

The development of the connectivity of agricultural tools is leading to important progress in the agricultural sector. The development of precision in the sector is now possible and it will increase the clarity of the industry. On the other hand, significant challenges will be faced as data exchanges in the business ecosystem and the need to invest in new infrastructure and tools are a necessity.

Predictive maintenance

Another reason to apply connectivity to a company in the agricultural sector is predictive maintenance. Deployments and connectivity enables the manufacturers to track the usage of the product. They can detect at a very early stage a loss of performance and offer preventive maintenance operations. In addition, the data collected helps the manufacturer to better understand the needs and usages to improve its line of products.

Another use of collecting data is to improve production practices, crops and tools. This approach could enable productivity increases and optimise the use of fertilizers, herbicides and fuel.

According to an article by Jess Noris and Jessica bland, published in Nesta.org (https://www.nesta.org.uk/blog/precision-agriculture-almost-20-increase-in-income-possible-from-smart-farming/) the collection of data could enable a 20% increase in income while reducing herbicide and fuel consumption by 10% – 20%.

However, these use cases will take time to deploy as they require extensive data collection and exchanges at the level of the ecosystem (enabling data analysis over several exploitations).

Connected ecosystems

The development of precision agriculture is based mainly on the ability to collect and analyse data. But to achieve these results and optimise production, the data needed to be gathered and analysed even further to detect patterns on farms/exploitations. This implies the development of data exchange mechanisms, and the collaboration of numerous factors with numerous and potentially conflicting interests.The organisation of these data exchanges is set to be a crucial spot in the value chain with the ability to generate knowledge from data and set up a business model of optimisation services.

Fun fact!

4.1 Million

According to the book <Industry 4.0: Managing the digital transformation>, this is the number of data points the average farm will generate by 2050!

Source: Industry 4.0: Managing The Digital Transformation By Alp Ustundag, Emre Cevikcan

Tasks

H5P: https://h5p.org/node/726338

8.3 How are drones revolutionising agriculture

Farmers and in general anyone in the agricultural industry should be prepared to take on new technologies for producing food, increasing productivity, and making sustainability a priority. Drones are part of the solution, along with closer collaboration between governments, technology leaders, and industry.

Here are 6 ways drones can assist in agriculture:

1. Soil and field analysis: Drones can be helpful at the start of the crop cycle. They are able to produce 3-D maps for the early soil analysis, which is useful in planning seed planting patterns. After planting, drone-driven soil analysis provides data for irrigation and nitrogen-level management.

2. Planting: Start-ups have created drone-planting systems that achieve an uptake rate of 75% and decrease planting costs by 85%. These systems shoot pods with seeds and plant nutrients into the soil, providing the plant all the nutrients necessary to sustain life.

3. Crop spraying: Distance-measuring equipment, meaning ultrasonic echoing and lasers, enables a drone to adjust altitude as the topography and geography vary, and thus avoid collisions. Consequently, drones can scan the ground and spray the correct amount of liquid, modulating distance from the ground and spraying in real time for even coverage. The result: increased efficiency with a reduction of in the amount of chemicals penetrating into groundwater.

*Experts estimate that aerial spraying can be completed up to five times faster with drones than with traditional machinery.

4. Crop monitoring: Vast fields and low efficiency in crop monitoring together create the largest obstacle in farming. Unpredictable weather conditions make the process even more challenging which increase risk and field maintenance costs. Previously, satellite imagery offered the most advanced form of monitoring. But there were drawbacks. Images had to be ordered in advance, could be taken only once a day, and were imprecise. Furthermore, these services were extremely costly and the images’ quality was low especially on days where the weather was poor. Today, time-series animations can show the precise development of a crop and reveal production inefficiencies, enabling better crop management.

5. Irrigation: Drones with hyperspectral, multispectral, or thermal sensors can identify which parts of a field are dry or need improvements. Additionally, once the crop starts growing, drones allow the calculation of the vegetation table, which describes the relative density and health of the crop.

6. Health assessment: It’s essential to assess crop health and spot bacterial or fungal infections on trees. Drone-carried devices can identify which plants reflect different amounts of green light and NIR light, by scanning a crop using both visible and near-infrared light. This information can produce multispectral images that track changes in plants and indicate their health. A speedy response can save an entire crop. In addition, as soon as a sickness is discovered, farmers can apply and monitor remedies more precisely. These two possibilities increase a plant’s ability to overcome disease. And in the case of crop failure, the farmer will be able to document losses more efficiently for insurance claims.

Tasks

H5P: https://h5p.org/node/726348

8.4. Challenges in Agriculture

Adoption

To fully adopt 4.0 technologies in agriculture will take time, although the practices and mindset in the agricultural domain are positive. This sector will face significant challenges from standardising technologies to being able to invest into modern equipment and infrastructures that can support this.

The development of Agriculture 4.0 requires the technological equipment to be compatible with its standards. With the lifespan of agricultural equipment, these standards are fundamental

Indeed, given the lifespan of agricultural equipment, standards are a necessity to ensure that any choices made (mainly technological, for example software) are compatible with the newest equipment and is supported by the manufacturers and other industrials.

The need to have data exchange and communication standards that link the different systems together in a unified system covering all aspects of the agricultural exploitation, is a huge challenge to be adopted in Industry 4.0.

Farmers

Another challenge in the adoption process, is the ability of farmers to invest and modernise their equipment and practises. Very often, the major issue with farmers are the low economic funds, with a very small ability to invest in new equipment and a limited access to credit.

Another factor in the adoption of Agriculture 4.0 is age. According to an article published by Euroactiv (Farming 4.0: The future of agriculture?), in 2013, over 56% of farmers in Europe are over 55 years old. Due to this, the digital skills of the workforce are limited and require additional investment in training to adopt technologies.

Furthermore, the willingness and ability to invest in new technologies face a risk of creating important gaps in production abilities between regions and exploitations.

Tasks

H5P: https://h5p.org/node/728210

8.5 The Future of Agriculture in Industry 4.0

View all videos in this section to get an idea of the evolving future of Agriculture in Industry 4.0 (or Agriculture 4.0)

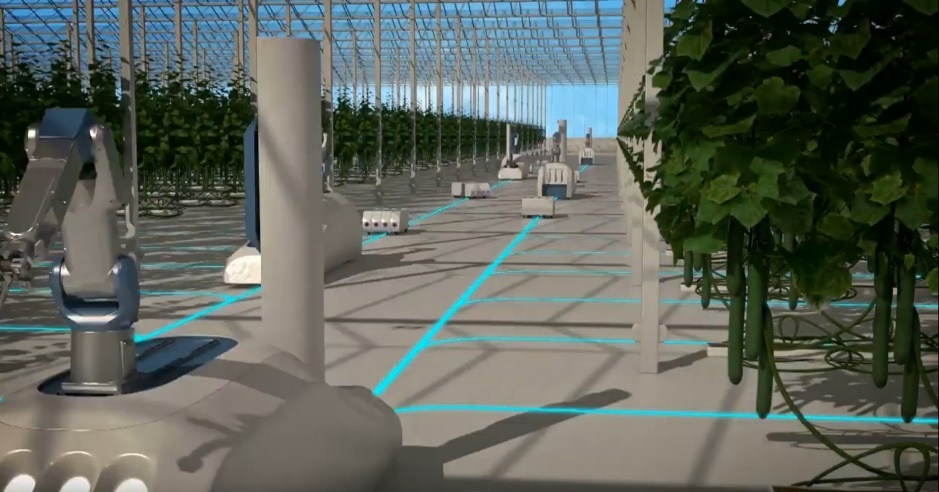

Crux Agribotics’ vision on Agriculture and how Robots with Vision and machine learning will automate the handling of crops end-to-end.

Video 2

Video 2

This video was created by WolkAbout. It explains how their IoT Platform delivers all the features necessary to build a Smart Farming system, through the example of this video.

Tasks

The video here is a summary of everything that has been analysed in topics 8 – 8.5, with some good practises from around the world, of Industry 4.0 implementation.

H5P: https://h5p.org/node/729212

9. Industry 4.0 in the Food and Beverage Sector?

According to Keith Thornhill – Head of Food and Beverage at Siemens Digital Industries, once a food manufacturer invests in some monitoring tools, that could enhance the production line, such as start to calculate almost immediately where productivity gains can be made, or where energy costs can be cut, or how the amount of downtime can be reduced through predictive maintenance, “the potential of digitalisation becomes clearer and more appealing”.

4.0 for Food and Beverage

Food and Beverage manufacturers that implement Industry 4.0, operate on two basic pillars:

- Information and process/product transparency

- Decentralized decision-making

Food manufacturers that implement 4.0 find their organisations are better equipped to control their processes. The effect this has to the company, is that there is more time to market their products, contribute to improving the global regulatory compliance, produce clean product labels with accurate, efficient ingredient management and more technologically responsive solutions to deliver maximum customer value at the lowest costs.

Managing, sharing and protecting data

Industry 4.0 directly impacts regulatory compliance for manufacturers who are in the Food and Beverage sector. Product data sharing, such as raw ingredients specifications and compliance-related information is now compulsory. In addition, 4.0 technology supports platforms that make the essential information available to shareholders throughout the supply chain.

Product data management is critical for global food and beverage manufacturers.

Infrastructure options such as Software as a services (SaaS) and Product lifecycle management in the cloud (Cloud PLM), are used for global supply chains in cyberspace. These are quickly becoming a key asset for manufacturers who operate across international borders and needed to comply with regulations while protecting data.

Food for thought

According to Severin J. Weiss – the CEO of SpecPage (global expert in integrated software process solutions for recipe-based food and beverage manufacturers), the food and beverage industry generates 1.8 trillion dollars per year worldwide. If Industry 4.0 replaced the older technologies, positive changes, including trends and consumer behaviours, global regulatory compliance and legal requirements as well as increasing specializations deliver unremitting challenges for food manufacturers. Digital networking of all processes can provide innovative solutions.

For the food and beverage sector, Industry 4.0 trends to identifying opportunities and implementing specific measures for best practices, by employing data to achieve a strategic, competitive advantage.

Tasks

For further reading: https://www.newfoodmagazine.com/article/91347/industry-4-0/

H5P: https://h5p.org/node/730850

9.1. Challenges and Benefits of Industry 4.0 in the Food and Beverage Sector

4.0 Challenges

In order for manufacturers to introduce the idea of Industry 4.0 into their businesses, the ideology of ” New business models require new strategies” should be the main concept. For businesses who rely on spreadsheets and enter data manually this concept will prove difficult. Severin J. Weiss, CEO of SpecPage (global expert in integrated software process solutions for recipe-based food and beverage manufacturers) insists that manufacturers should invest and embrace these new technologies in order to thrive in the global market.

4.0 Benefits

When the technologies of Industry 4.0 are introduced to the Food and Beverage sector, manufacturers will be able to quickly adjust and actively manage the rapid changes of food products, based on demand, while increasing traceability and transparency in the supply chain, and eliminating any risks associated with regulatory compliance.

To ensure better quality control, lab processes and data specification must be simplified and communicated clearly. By doing this the organisation ensures it has streamlined operations and could potentially achieve sustainable growth and return on investment (ROI).

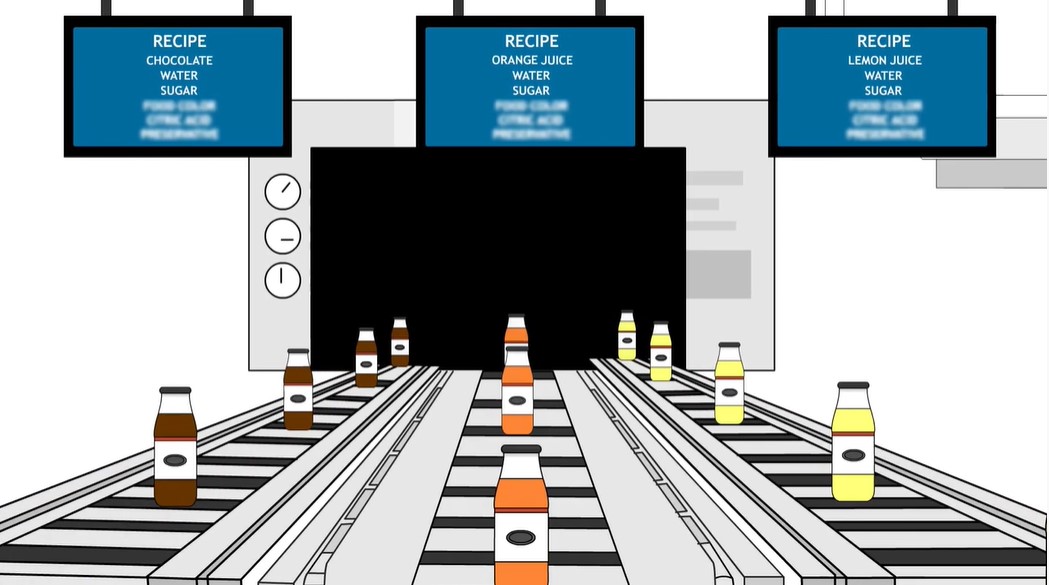

This video explains some benefits of Industry 4.0 in the Food and Beverage sector by showing how companies can use digitalization to dramatically increase flexibility, enhance consumer responsiveness, and improve productivity.

https://www.youtube.com/watch?v=kGb6utklQwk

Tasks

H5P: https://h5p.org/node/730876

9.2. Quality Control in the Food and Beverage Sector

Industry 4.0 has taken over the food manufacturing process in many ways. By integrating high-tech image processing, industrial robots are programmed in order to “see” and react to different situations based on the clearly defined parameters. This mean that the robots are able to identify different various food products on the same process line and simultaneously perform tasks, by identifying issues on the spot. The robots have been programmed with digital image processing. These consist of a series of processes that capture contactless, real time imaging, visual images sent to the computer and automatic analysis based on the results or measurement readings.

This is very beneficial for the food and beverage quality inspection, as it is able to certify labelling accuracy, colours, volume and/or height. This could potentially help inspect the entire manufacturing process from beginning to end with very little margin for errors.

The analytical monitoring enables the robots to perform necessary adjustments while in process. This ensures the required food safety standards are fulfilled and allows early detection of defects which by default reduces food waste and recalls.

To sum up, the 4.0 technology has resolved the limitation due to human imprecision, fatigue and variation in operators’ judgment. Simultaneously, the 4.0 technology is able to store data automatically for the documentation purpose and evidence in the event of customer complaint.

This video shows the vision of the Cognex company, by introducing barcode reading technologies in order to help manufacturers around the world improve product quality by tracking products through the supply chain, eliminating defects, and enabling automation.

https://www.youtube.com/watch?v=L66OiQs628U

Tasks

For further reading: https://www.researchgate.net/publication/333062733_Short_review_Application_Areas_of_Industry_40_Technologies_in_Food_Processing_Sector

H5P: https://h5p.org/node/730997

9.3. Food & Beverage Traceability with 4.0 Technologies

Traceability is the ability to locate an animal, commodity, food product or ingredient and to follow its history in the supply chain forward (from source to consumer) or backwards (from consumer to source) by recoding the process. This particular process becomes very costly and complex with the integration of 4.0 technologies. The complexity can be linked to the unique characteristics of the food materials that undergo a transformation from the bulk raw material to individual food products in the manufacturing processes. Another challenge is that the food processes are majorly operated by humans which can be difficult to monitor. Quick Response (QR) code and Radio Frequency Identification (RFID) have been adopted in food supply chain as to automate the identification and tracking of food.

An example of RFID application is for meat. The system records the complete chain from the farm, to the slaughterhouse, to the processing factory to the retailer. The traceability data is gathered and registered through RFID readers, and sent to the central database. At specific places, there are devices where a consumer can read data from the central database and get the required information about the meat. Other foods that have been applied with RFID system are dairy, bakery, beverages, sushi, pasta and coffee.

Some of the information on these products can be read by using the RFID readers provided by the resellers and/or retailers, by the web (browser personal computer) and smartphone applications (APP) when the RFID tag code is inserted. A less expensive alternative for the traceability of products is the QR code system, where consumers can acquire information related to their food by scanning the code. This can also be done by using a reader application installed on the smartphones.

Tasks

For further reading: https://www.researchgate.net/publication/333062733_Short_review_Application_Areas_of_Industry_40_Technologies_in_Food_Processing_Sector

H5P: https://h5p.org/node/731028

9.4. Automation and Customised orders

Automation for repetitive tasks

Automation for repetitive everyday tasks such as loading/unloading, assembly, packaging, pick and place, sorting, piling and spacing at very high speeds, have undoubtedly have been the robot’s sector. These kind of tasks are often found in the food sector. Manufacturers are trying to slowly replace the human workforce with robots, as they are more efficient and with less room for errors. Other benefits gained from this is the ability to satisfy the growing need of supply and demand, the food safety and hygiene, simplifying maintenance and preventing human injuries. A technology that is often applied in the food and beverage industry is the gripper technology. The gripper is a sub-system of an equipment that comes into contact with a gripped object. The gripper system is able to not leave any visible marks on the items after gripping them and high hygiene standards. Between the surface of the food and gripper there is negative pressure which holds the products. With this technology there is no need for pipes or tubes that cannot by easily cleaned. Other tasks such as slicing, deboning, portioning, skewing, filling and sorting are also possible with this technology.

Customised Orders

The main objective on Industry 4.0 is to achieve individual customer needs and preferences. This effects areas such as order management, product design, research and development, commissioning, shipment, utilization, recycling of the products and other related services. With the increasing of customisation in customer requirements, the technologies for manufacturing or 3D printers have turned to food manufacturing. In the most basic principal, products that are manufactured by a 3D Food printer are in layers in a particular process according to the recipe. A newer category of 3D printer called binding printers is able to “glue” materials together with a type of edible cement. The latest tech of 3D printers’ features nozzles, lasers, syringe and robotic arms working on powdery material to produce customized patterned chocolate or geometrically different pastry. Other possible customizations include taste, nutritional content, texture and colour

The technology has opened the possibility to produce personalized products and therefore, provide the companies an access for a new market opportunity that is focused on the customers who enjoy purchasing exclusive products or required specific diet for health. This technology, when implemented in the manufacturing sector could potentially solve producing products that have a complex geometry or required tedious assemblage. According to Noor Zafira and Noor Hasnan and Yuzainee Md Yusoff, 3D food printers have the potential to make a similar breakthrough as with the microwave back then in 70’s, where the users are able to make fresh meals at home quickly.

Tasks

For further reading: https://www.researchgate.net/publication/333062733_Short_review_Application_Areas_of_Industry_40_Technologies_in_Food_Processing_Sector

H5P: https://h5p.org/node/732624

9.5. Augmented Reality

Marketing

Another 4.0 technology that has been able to assist the Food and Beverage Industry is Augmented Reality (AR), which for this sector has been used for marketing purposes. With the available mobile technology upgrades in built-in cameras, sensors and mobile cloud computing, we now have AR on our mobile devices. This technology allows the consumer to engage personally with the products and closely examine them. The consumer is able to see details about the product such as the price, measurement and calories, though his live-camera. They are also able to play games with the food, conduct various tests and inform themselves on available promotions.

Here is an example of a LocateAR Starbucks Demo. This is an example of an Augmented Reality geolocation platform that enables businesses to rapidly design and deploy targeted location‐based AR experiences.

This advantage has not only cut costs in term of logistics, resources, advertisement materials and marketing personnel but also saves time as well as the effort for the preparation of multiple marketing gatherings. Although the technology seems to be advantageous for the marketing sector, it is also able to store and provide instant data about the customer behaviour and feedback without having to perform the traditional post-purchase survey. In addition, the use of AR enables companies to educate the consumers about their food products.

Training

Another advantage of AR is enhanced learning. An example of this achievement was in teaching. A test was administrated at plumbing students, that AR outperformed the traditional ways of teaching. The task was to assemble a water pump. The first group of students were shown the conventional 2D engineering drawings and the second group received information through AR. The second group were able to complete the task in approximately 8 times faster than learning from observing the engineering drawing.

The AR technology has progressed in many ways over last years. It has been used resourcefully to train various domestic tasks such as baking, planting and cooking. An example of this is an instructional video for the banoffee recipe which was designed by an artist Romain Rouffet, who is a Creative Technologist at Adobe. Viewers are able to drag their cursor around the screen to view and zoom in or out of the pie from different angles. Such visual recipes are potentially a sign of an innovative training method that can be applied not only in the foodservice sectors but also for other applicable operations. An advantage of this, is the reduction of cost in providing personalised trainings by using a video screen and it being available to a large number of students/trainees. This is important for the food and beverage industry as it will significantly reduce the “trouble” and cost of storing or preparing food and beverage products that have a short shelf-life and over time changing the quality. Another benefit of this technology is that trainings would now be a lot more effective. The use of visuals is able to reduce mental load and processing. This results to students/trainees being able to understand the subject faster. In food and beverage manufacturing, this type of training is important to prevent the them from disturbing the production activities.

Tasks

H5P: https://h5p.org/node/740249

10. Industry 4.0 and the challenges for the government

The challenges

Industry 4.0 challenges governments both positively and negatively.

On the one hand, it helps governments nurture an open, flexible, knowledgeable and skilled economy, by promoting trade outside of the traditional ways, by improving the effectiveness of the healthcare system and offers an advantage to those who know how to make best use of emerging technologies. On the other hand, governments could find themselves helpless against mega corporations, especially of taking into consideration the development of larger countries such as China and the U.S. The people will most probably start using technology for more autonomy, which will confront the power of governments and its institutions. An example of blockchain technology (meaning a growing list of records – blocks, that are linked using cryptography. Each block contains a cryptographic timestamp and transaction data. A blockchain is resistant to modification of data) is banking and personal finance. People could choose to trade with unofficial currencies such as bitcoins rather than official currencies run by central banks.

If governments fail to adapt to the new technologies, they will not be able to achieve the necessary efficiency needed for the growing demand of the public and cause damage to the reputation of the government. A study that was carried among hospitals and clinics in the UK, found that the most common complaint was the inability or limited access to Wi-Fi in these areas. Public areas will have to meet the peoples demands in the very near future.

What can be done?

David Lye, the director of Sami Consulting, stated in a report published by GE Reports (ge.com/reports) identified three scenarios on how the governments could deal with Industry 4.0.

- Managing the Market: The EU commission published its “Digital Single Market” strategy, for the best possible access to the online world for individuals and businesses and setting a framework of rules in which it expects technological changes to take place. The aim is to try to ensure stability and fairness for all.

- Taking Control: Large countries that do not have strong traditions in terms of Democracy, might attempt to introduce the newer technologies for either economic, domestic political or aggressive ends. The risk is that freer countries might be able to make faster progress and developing businesses, while taking advantage of countries who are trying to catch up.

- Open for business: Smaller governments might not be able to control the technologies of Industry 4.0, but they could attract invest, such as alluring tax regimes (for example Cyprus has one of the lowest EU tax corporates at 12.5%), investment in infrastructure (such as 5G) and being open to trade worldwide (a great example of a country that enlists all the above would be Singapore).

To conclude, the governments need to plan an approach to manage the impact of the transition to the new technology.

For more information on this article please click here

Tasks